Ultrasonic machining, a non-traditional manufacturing process, has gained popularity in various industries due to its unique advantages. This innovative technique utilizes ultrasonic vibrations to remove material from workpieces with high precision and efficiency. In this article, we will explore the benefits of ultrasonic machining that make it a preferred choice for many manufacturing applications.

High Precision Machining

One of the key advantages of ultrasonic machining is its ability to achieve high precision in the machining process. The ultrasonic vibrations create a fine abrasive slurry that effectively erodes the workpiece material, resulting in intricate and accurate cuts. This precision is crucial in industries such as aerospace and medical, where components must meet strict tolerances for optimal performance.

Improved Surface Finish

Another significant advantage of ultrasonic machining is the superior surface finish it can achieve on workpieces. The process generates fine abrasives that act as cutting tools, producing smooth surfaces with minimal roughness. This high-quality finish eliminates the need for additional finishing operations, saving time and resources in the manufacturing process.

Versatility in Materials

Ultrasonic machining is highly versatile and can be used to process a wide range of materials, including hard and brittle ones that are challenging to machine using conventional methods. From ceramics and glass to composites and semiconductors, ultrasonic machining can effectively shape and cut these materials with precision and accuracy. This versatility makes it a valuable tool for industries that work with diverse material types.

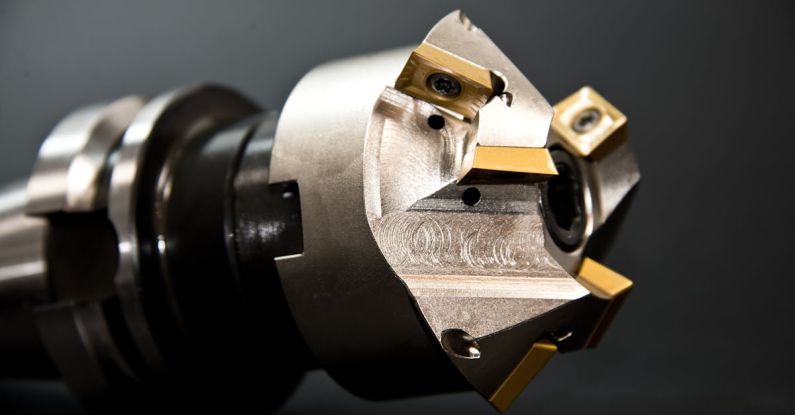

Reduced Tool Wear

Unlike traditional machining processes that rely on cutting tools, ultrasonic machining does not involve direct contact between the tool and the workpiece. Instead, the abrasive slurry generated by ultrasonic vibrations does the cutting, resulting in minimal tool wear. This leads to longer tool life and reduced maintenance costs, making ultrasonic machining a cost-effective solution for manufacturers.

Enhanced Energy Efficiency

Ultrasonic machining is known for its energy efficiency compared to conventional machining methods. The process requires less power consumption due to the use of ultrasonic vibrations to remove material, resulting in lower energy costs and environmental impact. This eco-friendly aspect of ultrasonic machining aligns with the growing emphasis on sustainable manufacturing practices.

Faster Machining Speeds

In addition to its precision and efficiency, ultrasonic machining offers faster machining speeds, contributing to increased productivity in manufacturing operations. The rapid material removal rate achieved through ultrasonic vibrations allows for quicker turnaround times on production runs, helping manufacturers meet tight deadlines and customer demands.

Complex Geometries

Ultrasonic machining excels in creating complex geometries and intricate shapes that may be challenging to achieve with traditional machining methods. The flexibility of the process enables manufacturers to produce custom components with precision and accuracy, expanding design possibilities and pushing the boundaries of what is achievable in manufacturing.

Cost-Effective Manufacturing

Overall, the advantages of ultrasonic machining culminate in a cost-effective manufacturing solution for various industries. From reduced tool wear and energy efficiency to improved surface finish and machining speeds, ultrasonic machining offers a competitive edge in terms of both quality and efficiency. By harnessing the benefits of this advanced machining technology, manufacturers can optimize their processes and stay ahead in today’s competitive market.

In conclusion, ultrasonic machining presents a host of advantages that make it a valuable tool for modern manufacturing. Its precision, surface finish, versatility in materials, reduced tool wear, energy efficiency, faster speeds, ability to create complex geometries, and overall cost-effectiveness position it as a preferred choice for industries seeking innovative solutions to their machining needs. Embracing the benefits of ultrasonic machining can lead to enhanced productivity, quality, and competitiveness in the ever-evolving landscape of manufacturing.