The field of microelectronics fabrication has revolutionized the way we interact with technology, enabling the creation of smaller, faster, and more powerful devices. However, as this industry continues to advance, it faces a myriad of challenges that must be overcome to meet the demands of an increasingly complex market. From shrinking transistor sizes to ensuring high yields, the challenges in microelectronics fabrication are diverse and ever-evolving.

Shrinking Transistor Sizes

One of the primary challenges in microelectronics fabrication is the continual push for smaller transistor sizes. As technology advances, the demand for smaller and more efficient devices grows, necessitating the development of ever-smaller transistors. Shrinking transistor sizes present numerous challenges, including the need for precision manufacturing techniques, tighter process controls, and enhanced materials engineering. Additionally, as transistor sizes approach the atomic scale, issues such as quantum effects and leakage currents become more pronounced, requiring innovative solutions to maintain device performance and reliability.

Increasing Complexity of Integrated Circuits

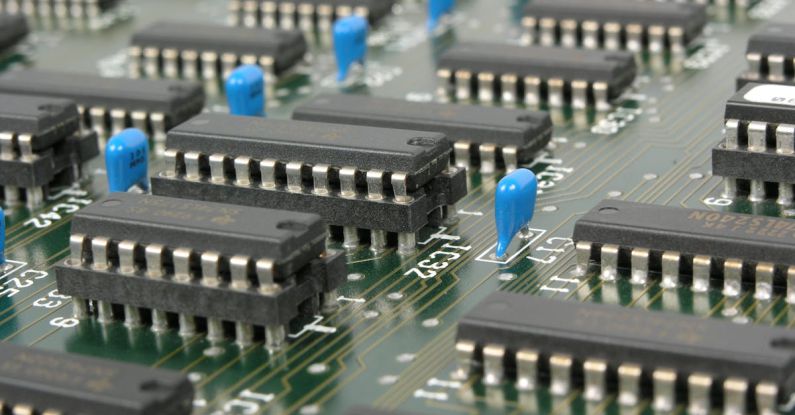

Another significant challenge in microelectronics fabrication is the increasing complexity of integrated circuits. Modern electronic devices contain billions of transistors packed into a tiny silicon chip, each interconnected in intricate ways to perform specific functions. As the complexity of integrated circuits continues to grow, the fabrication process becomes more complex and challenging. Fabricating these highly integrated circuits requires advanced lithography techniques, sophisticated materials deposition methods, and precise etching processes to ensure the functionality and reliability of the final device.

Yield Enhancement and Defect Reduction

Achieving high yields and reducing defects during the fabrication process is a critical challenge in microelectronics manufacturing. Even a single defect in a silicon wafer can render an entire chip unusable, leading to significant production losses and increased costs. To address this challenge, manufacturers must implement rigorous quality control measures, optimize process parameters, and develop innovative defect detection and mitigation strategies. Additionally, as devices continue to shrink in size, the detection and repair of defects become increasingly challenging, requiring advanced inspection tools and techniques to ensure high yields and product reliability.

Materials Compatibility and Integration

The compatibility and integration of materials present another set of challenges in microelectronics fabrication. As new materials are introduced to enhance device performance and functionality, ensuring their compatibility with existing fabrication processes and materials becomes crucial. Integrating novel materials into the fabrication process requires a deep understanding of their properties, interactions, and potential impacts on device reliability. Moreover, as the industry transitions to new technologies such as 3D integration and heterogeneous integration, the challenges of materials compatibility and integration become even more complex, necessitating innovative solutions to enable seamless integration of diverse materials and processes.

Cost and Time-to-Market Pressures

Cost and time-to-market pressures are constant challenges in the competitive microelectronics industry. Developing and bringing a new device to market involves significant investments in research, development, and manufacturing, with tight deadlines to meet consumer demand and stay ahead of competitors. Balancing the need for rapid innovation with cost-effective manufacturing processes is a delicate balance that manufacturers must navigate to remain competitive in the market. Additionally, unexpected delays in the fabrication process or issues with yield and quality can have significant financial implications, underscoring the importance of efficient production processes and robust supply chains.

Innovative Solutions and Future Prospects

Despite the myriad challenges in microelectronics fabrication, the industry continues to push the boundaries of technology through innovation and collaboration. Research into new materials, manufacturing techniques, and process optimization strategies is driving advancements in device performance, energy efficiency, and reliability. With the rise of technologies such as artificial intelligence, Internet of Things, and 5G communications, the demand for advanced microelectronics continues to grow, presenting new opportunities and challenges for the industry. By embracing innovation, collaboration, and continuous improvement, the microelectronics industry can overcome its challenges and pave the way for a more connected and technologically advanced future.

In conclusion, the challenges in microelectronics fabrication are diverse and complex, requiring a multi-faceted approach to overcome. From shrinking transistor sizes to increasing complexity, manufacturers must address a range of technical, operational, and economic challenges to stay competitive in the fast-paced electronics market. By investing in research and development, fostering collaboration across the supply chain, and embracing innovative solutions, the microelectronics industry can overcome its challenges and continue to drive technological innovation for years to come.